Up Your Strategic Sourcing Game

As of June 2021, the United States and China are charting the future as a trade war has not helped either country’s economies compounded by COVID-19. The recent G7 Summit shows how the US in partnering with its allies to present a united front against China’s interests. Importantly, they agreed world leaders promised 1 billion COVID-19 doses to help the world heal. Longer term the vaccinations will help but in the short run many variants are slowing the recovery but there is significantly more hope in the business community. Both sides have also threatened qualitative measures that affect U.S. businesses operating in China. Negotiations are ongoing. Meanwhile, countries have responded to the COVID-19 pandemic with large economic stimulus packages as shutdowns cause worldwide planning and sourcing uncertainty. Manufacturers are suffering severe operations, personnel, revenue challenges & procurement and supply chain management.

Given the U.S. and Chinese tariffs and resulting trade wars, there is an emphasized importance of reducing supply chain sourcing risk in this current economic environment. Many companies are struggling to find key and minor parts as shortages increase and lead-times elongate. This article discusses supply chain current events, future trends, executive concerns with risks, and tangible results we have delivered with clients that have mitigated risk through supply chain diversity.

Beginning with the end in mind

We find that only two out of ten companies can be classified as true “mitigators” of supply chain risk. There are many ways to begin reducing supply chain risks:

- Reimagining the supply chain and sourcing strategy

- Reducing tariff impact by building a more efficient supply chain

- Realigning the global sourcing portfolio

- Revisiting the manufacturing, logistics, and contracting footprint

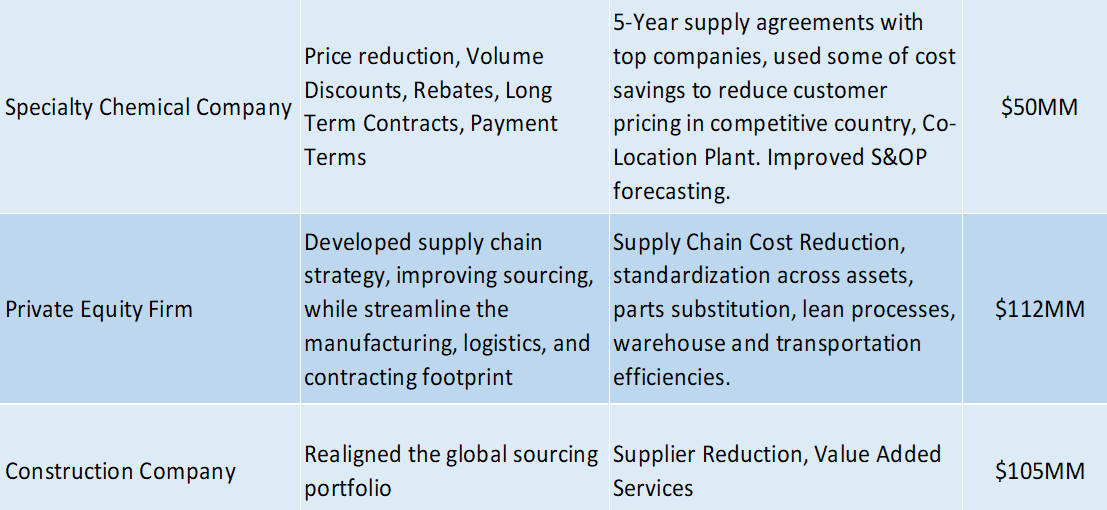

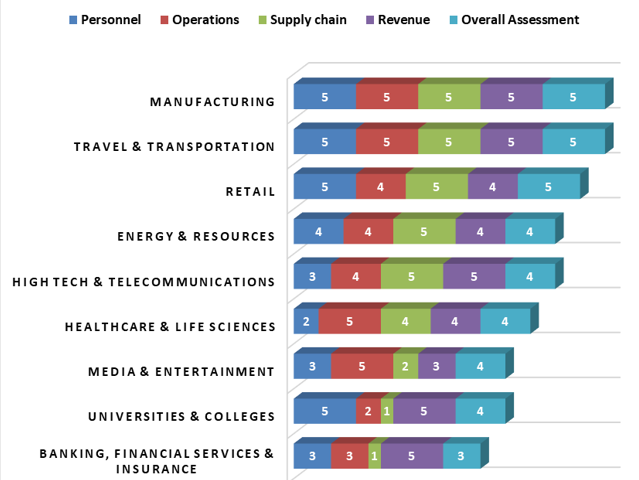

As shown below, we have uncovered procurement and supply chain management opportunities and mitigated risks across many industries.

How did we get to the current crisis?

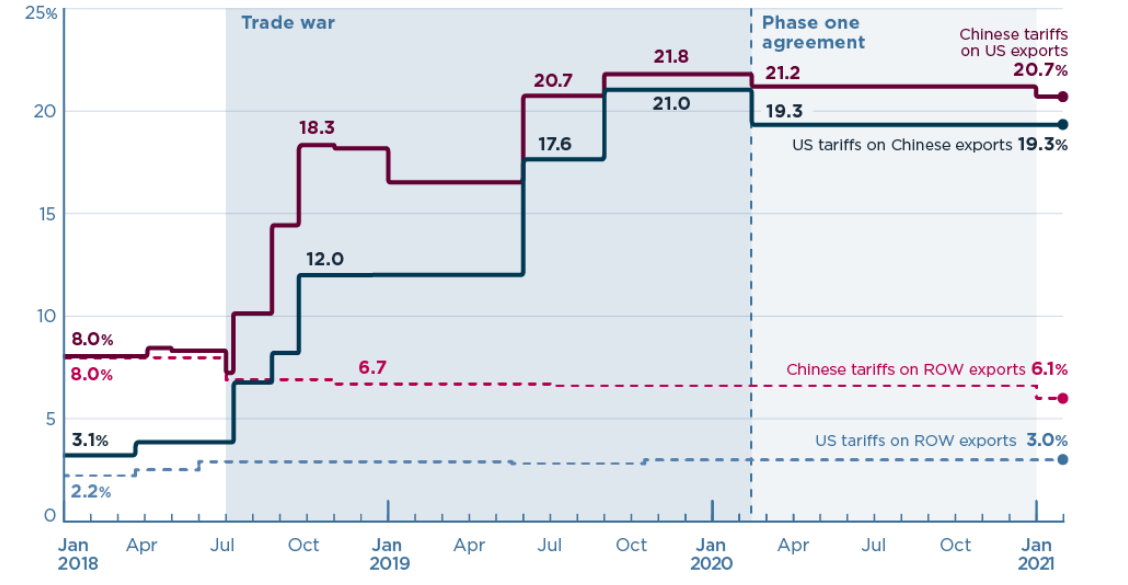

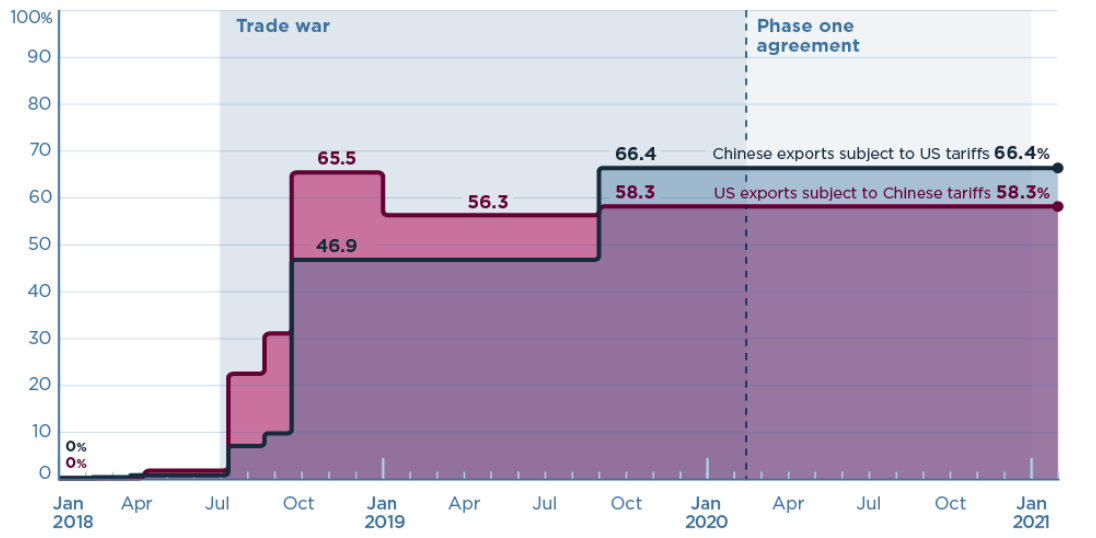

Understanding the historical landscape is increasingly important. Charts below show the US-China tariff rates and percent of US-China trade subject to tariffs since 2018.

![]()

Source: PIIE

![]()

What are top companies doing?

Companies across the United States are performing tariff related cost analyses and reaching similar sobering supply chain business conclusions:

• Lincoln Electric: The welding equipment and supplies maker is raising prices on so-called consumables via surcharges to offset the costs of tariffs.

• Alcoa: The aluminum-product manufacturer cut its profit forecast ranges by $500 million, citing tariffs on aluminum it imports from Canada.

• General Electric: The U.S. conglomerate, which faces $400 million a year in tariff-induced costs, is considering adjusting its supply chain to mitigate the effects.

• United Technologies: The company, which owns Pratt & Whitney, Carrier, and Otis, says tariffs are reducing its earnings. It is looking at cost-cutting measures to compensate.

Current State

COVID-19 has severely disrupted the supply chain, personnel, operations, and revenue of the manufacturing segment. Supply issues also plague Travel, Retail, Energy, High Tech, and Healthcare. The scale is 1 to 5; where 1 is minor impact and 5 is severe impact.

Key Questions

There is much uncertainty across an array of spend categories. Consequently, you, your executives, and company investors may be troubled by three gut checking supply chain risk questions:

1. Are you sourcing and manufacturing from the right countries given dynamic tariff and trade policy and COVID-19 risks?

2. Do you have the best supply partners, providing service and lead time needs of customers?

3. Can your supply chain teams execute projects with excellence to realize bottom-line impact?

Companies often get blind-sided by not launching initiatives that comprehensively address these questions. Strong companies completely mitigate their risks. Being great in one aspect is necessary but not enough. High-risk weaker companies are strategically flawed, have the wrong partners or lack project implementation.

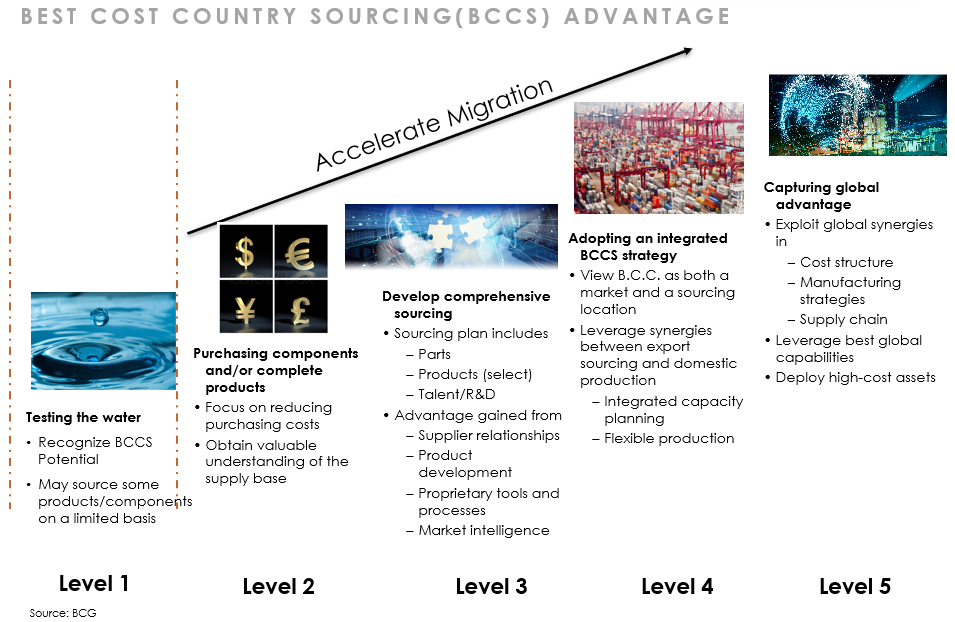

Rate your company’s global best cost country sourcing performance

We have three questions to ask you about your organization:

1. Are you just testing the waters (level 1) or capturing global advantage (level 5)?

2. Where would you place your competitors?

3. Where would you like to be?

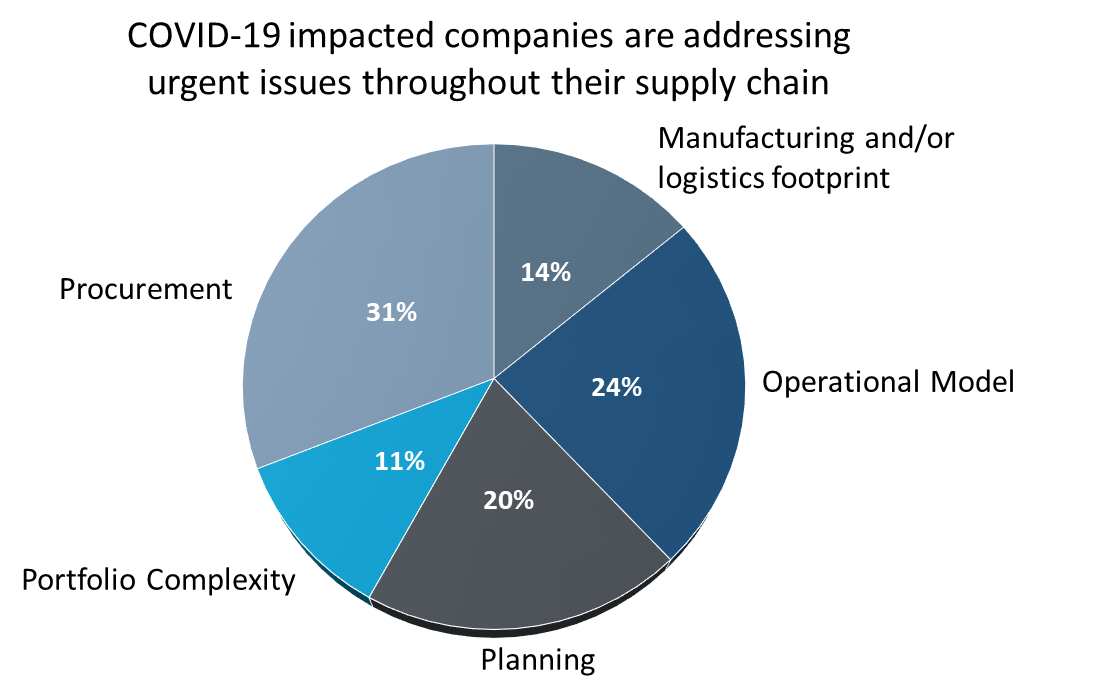

As COVID-19 is wreaking havoc on company supply chains, leaders are addressing issues on several fronts as a clarion call to action for immediate and post-crisis change. Where is your urgent focus?

Eliminate your company’s blind spots

We start with a brief supply chain and sourcing assessment to determine what is working in your organization – and identify blind spots in your supply chain.

You will find where your supply chain risk is located and where there is savings potential.

Contact:

Melzie Robinson

CEO

Paragon Results LLC

1600 Parkwood

Atlanta, GA 30339

mobile: 630.273.5231

mrobinson@paragonresults.com